꿈과 희망을 주는 기업, 동신이엔텍이 되겠습니다.

Business AreaHybrid Retrofit SystemHybrid Retrofit System for Hydraulics Machinery

Business AreaHybrid Retrofit SystemHybrid Retrofit System for Hydraulics Machinery

Hybrid Retrofit System

Hybrid Retrofit System for Hydraulics Machinery

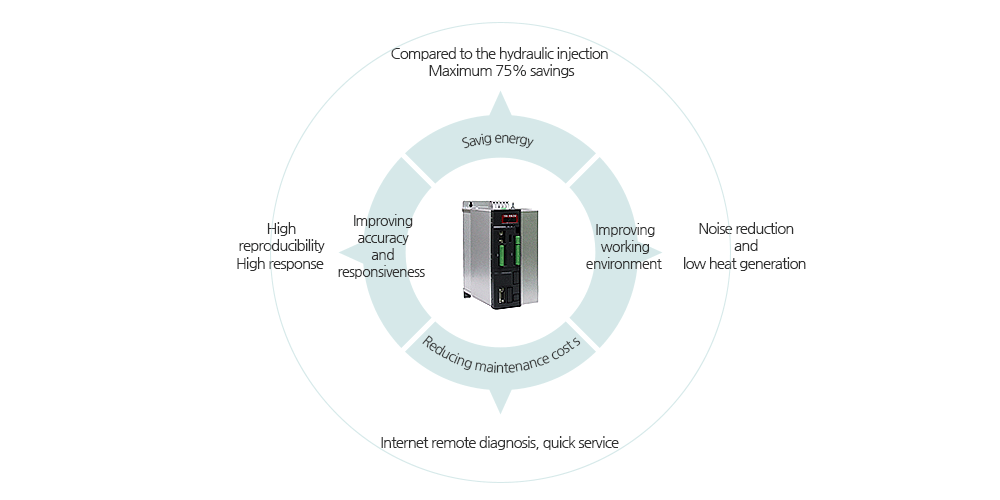

Hybrid Retrofit System for Hydraulics Machinery Servo Hybrid System is a hybrid system composing of the most advanced DRIVE, MOTOR, PUMP and other parts adequate for injection molding machine, pressing machine and etc. It is an electric and hydraulic integrated system applied of the most advanced technology, achieving maximum power saving (75%↑), high precision, high responsibility and eco-friendly effect.

Servo hybrid system, which controls only the necessary pressure and speed at the perfect timing, has all of economic, technical and environmental effects with both of electric and hydraulic machine’s advantages.

- Advantages of electric machine : high precision control by CLOSED LOOP, etc.

- Advantages of hydraulic machine : high pressur maintenance, low preservation cost, etc.

By retrofitting hydraulic machine to hybrid machine, it can present the same advantages and effects of new hybrid machine by converting its performance, functions and features.

Product Applications

Hybrid Retrofit System has an innovative advantage and effect when it is applied to the machinery using oil pressure.

- Injection Molding Machine

- Hydraulic Presses

- Blow Molding Machine

- Hydraulics

- Pump Device

- Textile Machinery

- Machine Tools

- Marble Processing Machinery

- Metal Forming Machine

- Recycling Process

- Food Industry

- Factory Automation

Product Composition

Servo Drive

- Built with PID CLOSED LOOP control mode

- Full safety in operation

- High-precision, high power, high responsiveness from flow and pressure contro

Servo Motor

- AC SERVO MOTOR, high speed, high-torque power-transmission

- Low inertia of rotor, high responsiveness, the best radiant heat efficiency, low noise

Servo Pump

- Low noise servo pump

- High-speed driving achieving high efficiency

- Hydraulic pump revolutions linear control, low energy low speed/high pressure holding

Servo Hybrid Retrofit Business

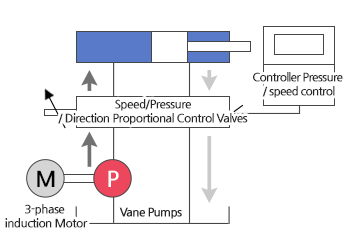

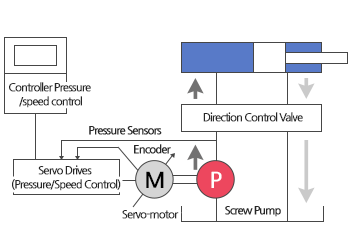

• Comparison of Hydraulic System and Servo Hybrid System of Injection Molding Machine

| Conventional Hydraulic System | Servo Hybrid System | |

|---|---|---|

| Configuration |  |

|

| Control Method |

|

|

| Driving Principle |

|

|

| Main Characteristics |

|

|